Introduction to Statistical Control

Today,

manufacturing companies face increasing competition due to raw material cost

and other factors like employees and resources. Therefore companies must

concentrate on strategies to improve their level to come best in the market. Companies

must try for continuous improvement in quality, efficiency and cost reduction.

Many companies still rely on inspection after production for quality analysis.

In recent trends, many control methods has come into existence which would

increase the product quality.

Control

plays a major part in every industry for the betterment of the process and the

quality. For this purpose, statistical approach is used in many organizations.

In statistics, controlling a variable attempts to reduce the effect of other

variables i.e., it is an observational study effect of one variable is measured

while all other variables are kept constant.For statistical control in research,

during experiments, researchers assign variables randomly to the treatment group

such that the variables are not interchanged and hence their effects are

observed independently, and the defects are found out easily if there occurs a

malfunction in the process.

There

are several mechanisms for the process control and quality control. Statistical quality

control refers, to the usage of statistical method that helps in monitoring and

maintaining the quality of products and services. Acceptance sampling method

and rejection method is followed based on the quality test conducted during

testing method.

Statistical Process Control (SPC)

On

the other hand, Process control is a discipline that deals with architectures,

mechanisms and algorithms in order to obtain an output for the desired range.

It is extensively used in industry in various parts of departments such as

power plants, manufacturing, production, Manufacturing and so on. It enables

automation and thus reduces human errors and wastage of resources.

Statistical process control is a processcontrol method that uses statistical

methods to monitor and control a process to ensure that the process operates at

its full potential.

SPC

is used to reduce the process waste and to eliminate the step-by-step

manufacture inspection. The concept of SPC was brought out by Walter A.

Shewhart in early 1920s along with control chart for understanding the process

and specification limits, eliminating assignable sources of variation and

monitoring the ongoing production products.

Statistical

Process Control (SPC) is

a branch of statistics that combines time series analysis methods with

graphical representation of data and thus helps to take a deep insight on data

more quickly and in fast decision-making. Although SPC was introduced in the

early before the six sigma approach it is still one of the most advantageous

methods used in most of the organizations. SPC data is collected in the form of

measurements of a product dimension or future or readings. The data is then

recorded and tracked on various types of control charts. The data can be in the

form of continuous variable or average.

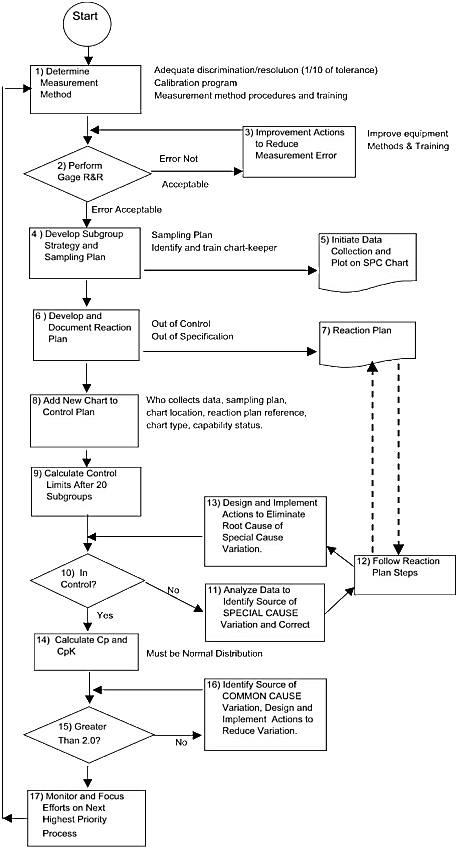

Fig.1-SPC plan implementation

It

helps in ensuring whether the process is stable or not. An example for the

process where SPC is applied is in the manufacturing lines. In industries,

those who manufacture on large-scale experience confusions and conflicts during

the process and the quality measurement. And as the reputation mainly depends

on the quality, these control method are quite useful and easy to be

implemented by the organization. It is more common in the manufacturing industries

and in organizations which operate in multiple streams like manufacturing,

production, testing and delivery.

SPC

seeks to measure the quality of work in process, and its implementation is

typically the first step towards total quality systems management. It is useful

process improvement technique in getting and keeping a process on target with

minimal variation. SPC emphasizes early detection and

prevention of problems, which can benefit to production of quality products and

hence time plays a major constraint in implementing SPC. SPC is cost-effective

as if the process changes, it leads to the wastage of the resources. Another

major problem in implementing SPC is the misunderstanding of the real concept

of SPC.

Control Charts

Statistical Control or Process Control can be

obtained by various statistical control charts and the best suitable method is

the usage of control charts. Control charts, also known as Process-Behavior

Chart is a statistical process control tool that determines if a process is

in stable state or overwhelmed. It is one of the most useful tool in the fields

of management and can be applied in any modes of management like planning,

organizing and in decision making. It is used to control the process when the

control goes out of hand. It is a graph that depicts how the process changes

over time.

Fig.2-Example of SPC Chart

The control chart changes according to the process and the outputs obtained in each and every process. A control chart is used to keep the process and quality under control. A control chart has a central line for the average, an upper line for the upper control limit and a lower line for the lower control limit. These lines are determined from historical data. The analysis of control chart indicates whether the process is under control or not. If not stable, the precautionary measures to make it stable can be taken. It is one of the seven basic tools of quality control.

Fig.3-Normal Distribution

Fig.4-terms used in Control Chart

The control chart uses various parameters such as normal distribution, mean, and standard deviation for the measurement of the variables by which the efficiency is determined. Normal distribution is defined as the heart of SPC as its typical Gaussian distribution curve les in the heart of the mathematical model that illustrates statistical process control. Normal distribution is based on principle of limitless totality.

Control

charts consists of control limits which are known as Tolerance limits of

the sample series. Control limits are used for the mean and mean variation of a

series. One of the most commonly used control chart for variable data is X bar

and R chart. X bar represents the average and it displays the variation in the

sample data collected. Once the chart is set up, the operator will measure

multiple samples and calculate the average. This value is recorded and depicted

in the chart.

Control

chart reveals the factors like variations in material properties, seasonal changes in temperature or humidity,

normal machine or tear, normal measurement variation. It also includes special

cause variation such as process shift, machine malfunction, broken tool and

inexperienced operator. These changes should be identified and corrective

actions should be taken.

Contents of Control Chart

Basically,

a control chart consists of points that resemble a statistic for measurement of

quality characteristic in samples that are taken at different times, the mean

of those statistic samples calculations, a central line at the value at the

mean of the statistic, the standard deviation calculations for the statistic

samples and the upper and lower limits that indicates the threshold between

which the graph is drawn.

Fig.5-Points on a SPC chart

The

chart may also contain warning and control limits

depending upon our needs. The purpose of control charts is to allow simple

detection of events that indicate the actual process change. SPC is used as a

real time method implementation in various organizations and baldor is one of

the examples for it.

Application

Baldor is one of the organizations that

implement SPC on the ongoing process in the management. It is one of the

leading producers of industrial electric motors, power transmission products

and generators. At baldor, the management believes in product quality as much

as production quantity to ensure the level of quality baldor decided to

institute a policy dedicated to consumer satisfaction and this policy was

entirely based on statistical process control. The management reveals that this

solution is user friendly for production and was quickly adopted by their

employees. SPC was instituted into baldor, a corporate culture with quality

personnel, engineers and managers all using data to improve processors.

After

the implementation of SPC, baldor evaluated the successful SPC techniques and

founded the user-friendly interface and better inspection tools and methods.

The methods produced faster, more accurate inspections with reduced cost. These

savings eliminated the handwritten charts and log books with control charts.

As, a result of this implementation, baldor was able to measure improvement in quality throughout the manufacturing

process.They reported 66% annual dollar savings while others reported only 63%

annual dollar savings. Baldor’s customers are on the winning end of quality

improvement and reported 48% reduction in warranty claims.

Conclusion

Recently,

an infinity QSProFicient software with SPC was developed that can detect

production errors as it occurs and such that it alerts you before it is too

late. It allows data to stream in real-time to a central quality control hub.

With this real time data you will be able to alter specific aspects of your

production.

This

will increase efficiency and provide maximum control over process and quality.

SPC Software is the tool that will allow this process to take place. It reduces

the monthly reports and the software provides fast

and accurate comfort so that take holders can confidently move forward with

organizations plans without any confusions. Hence, SPC has been proven as a

best solution for the upcoming challenges in the field of business.

More

Readings

Comments

Post a Comment